- Menu

- Search For Product Models

Search For Product Models

- cn

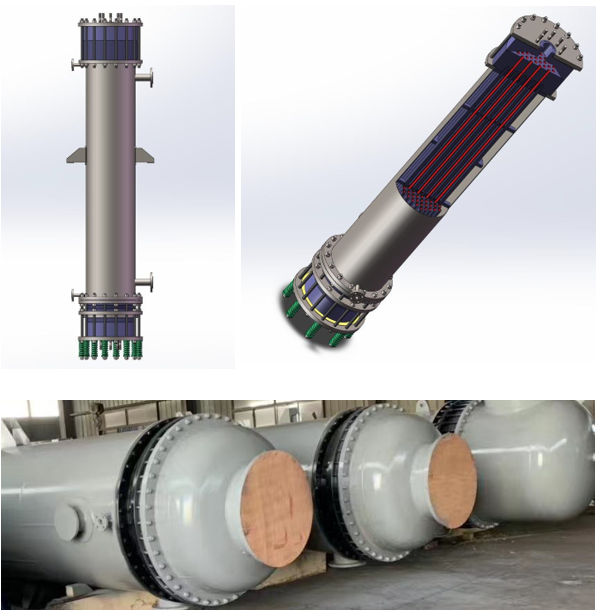

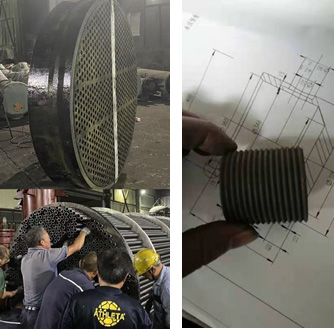

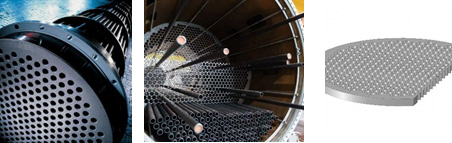

The shell and tube type graphite heat exchanger consists of an array of graphite tubes and tube sheets bonded together with an adhesive (or using single-tube mechanical seals). The tube bundle is placed inside a cylindrical shell, with end caps made from impenetrable graphite or other corrosion-resistant materials, fastened by bolts to form the complete unit. One fluid flows inside the tubes, while the other fluid flows over the outside of the tubes (through the shell). Heat is transferred through the graphite tube walls, and the fluids do not come into direct contact with each other.

Shell and tube type graphite heat exchangers are suitable for applications involving highly corrosive chemicals and are commonly used for cooling, condensing, and absorption, but can also be used for heating and evaporation. Depending on the pressure, temperature, and heat transfer efficiency of the process conditions, various types of impenetrable graphite tubes can be selected, including standard tubes, medium-temperature tubes, impregnated tubes, and specially reinforced tubes (such as carbon fiber-reinforced tubes and inner plug tubes).

Main Advantages

• Large heat transfer surface

• Excellent corrosion resistance

• Exceptional heat transfer performance due to adjustable cross-sections on both the tube and shell sides

• High operational safety

• Highly reliable equipment with low capital and maintenance costs

• Robust design

• Short delivery time

• Long service lif

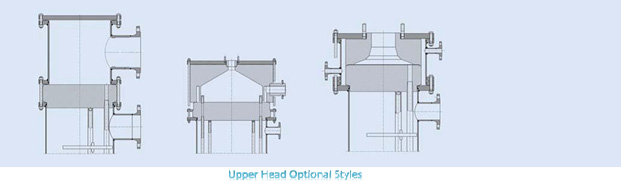

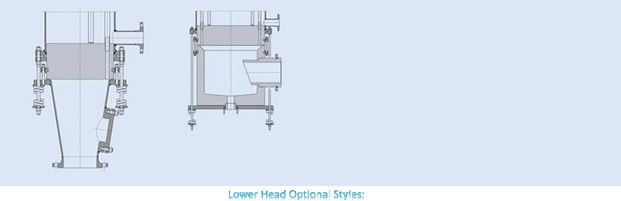

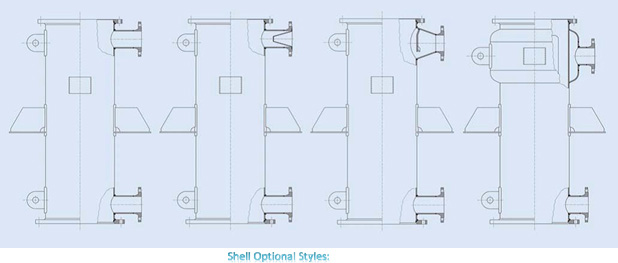

Design

• Internal plug-in for enhanced heat transfer

Main Features

• Design Pressure:Tube side: -0.1 (full vacuum) to +0.6 MPa,Shell side: up to 1.0 MPa

• Design Temperature: -60 to +160°C

• Heat Transfer Area: Up to 2000 m²

Details at a Glance:

Example Applications: