- Menu

- Search For Product Models

Search For Product Models

- cn

1. Introduction

A Stainless Steel Fusion Bond Heat Exchanger is a compact plate heat exchanger in which stainless steel plates are permanently joined using a fusion bonding (diffusion bonding) process.

Unlike traditional brazed or gasketed plate heat exchangers, this technology does not use copper brazing materials or elastomer seals, resulting in an all-stainless-steel construction.

Fusion bonded heat exchangers are specifically designed for applications that demand high cleanliness, corrosion resistance, mechanical strength, and long-term operational reliability.

2. Fusion Bonding Technology

Fusion bonding is a solid-state joining process characterized by:

Stacking precision-formed stainless steel plates

Applying high temperature and pressure

Creating a metallurgical bond at the molecular level

No melting of base material

No filler metals or brazing alloys

The result is a monolithic stainless steel heat exchanger, where the plates are permanently bonded without introducing dissimilar materials into the structure.

This eliminates risks associated with galvanic corrosion, filler material degradation, and material incompatibility.

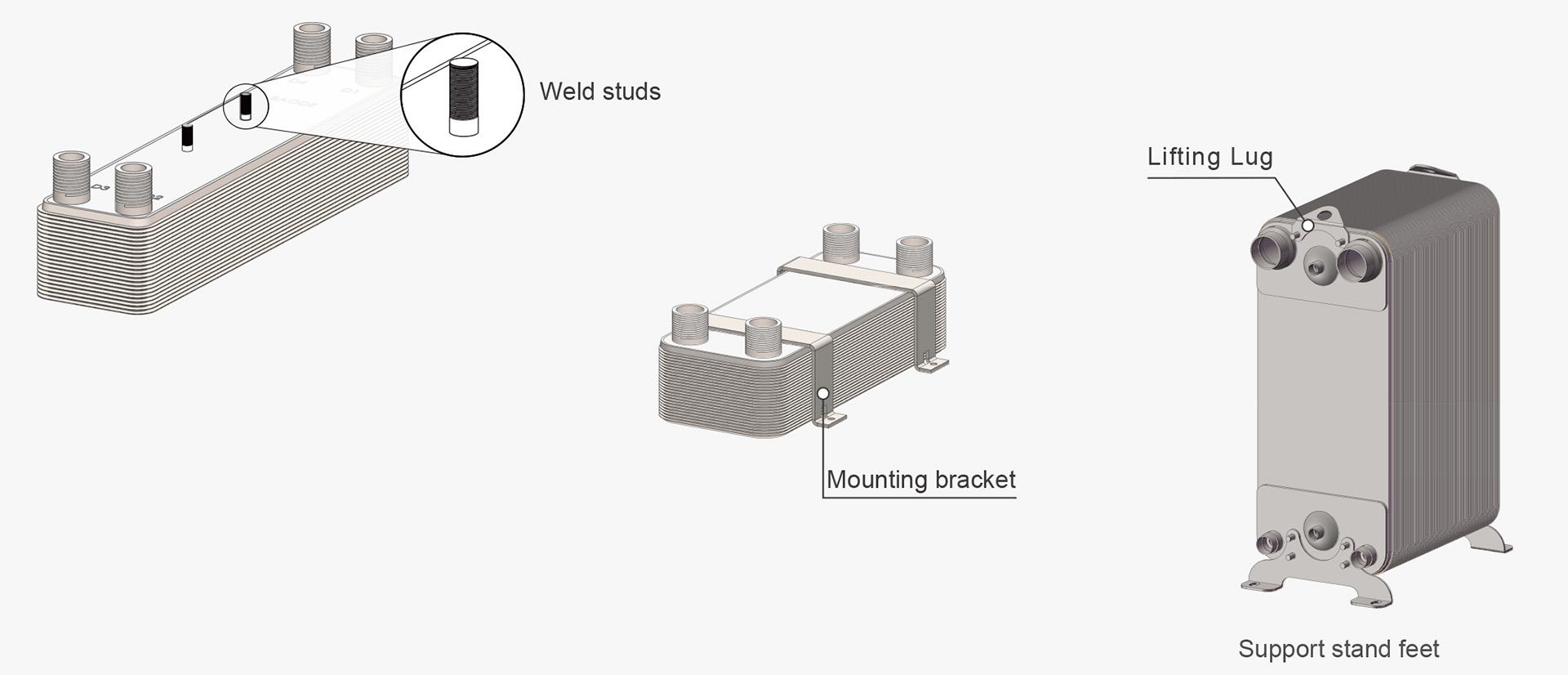

3. Construction Features

Key construction characteristics include:

100% stainless steel plates and bonding zones

Chevron or herringbone plate patterns for enhanced turbulence

Compact, gasket-free design

Uniform bonding across plate contact areas

High resistance to pressure and thermal fatigue

Because bonding occurs over large surface areas, fusion bonded heat exchangers exhibit excellent mechanical integrity and long service life.

4. Performance Advantages

High Corrosion Resistance

No copper or nickel exposure to process fluids

Suitable for aggressive or sensitive media

Compatible with deionized water, ammonia, CO₂, and other demanding fluids

Clean and Hygienic Design

No brazing materials that could leach into the fluid

Suitable for clean systems and high-purity applications

Smooth internal surfaces help reduce fouling

High Mechanical Strength

Excellent resistance to pressure fluctuations

Withstands frequent thermal cycling

Stable performance under dynamic operating conditions

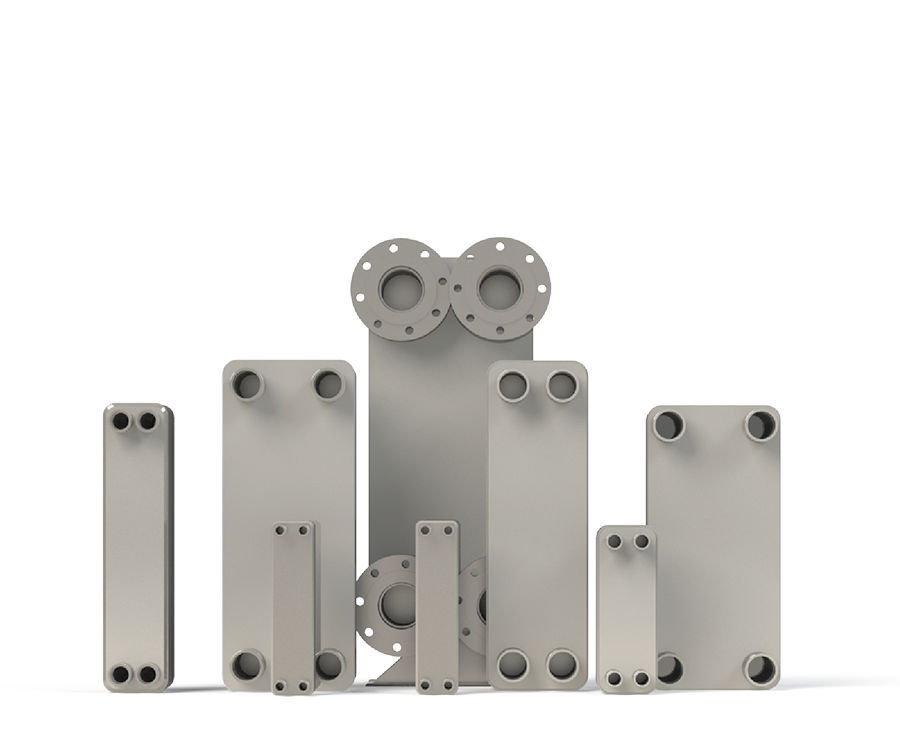

Compact and Efficient

High heat transfer efficiency due to optimized plate geometry

Smaller footprint compared to shell-and-tube designs

Reduced installation space requirements

5. Comparison with Other Heat Exchanger Types

Feature Fusion Bond Brazed Plate Gasketed Plate

Sealing method Solid-state metal bond Copper brazing Elastomer gaskets

Dissimilar metals None Yes Possible

Maintenance Maintenance-free Maintenance-free Periodic gasket replacement

Temperature resistance High High Limited by gasket material

Chemical compatibility Excellent Limited by brazing alloy Limited by gasket material

6. Typical Applications

Stainless steel fusion bond heat exchangers are widely used in:

Refrigeration and heat pump systems

Industrial process heating and cooling

District heating and cooling networks

Clean water and ultrapure water systems

Chemical and pharmaceutical processes

Applications where copper or elastomers are not acceptable

7. Operational Reliability

The absence of gaskets and brazing materials provides several operational advantages:

Minimal risk of internal leakage

Stable long-term performance

Reduced sensitivity to pressure shocks

Lower total cost of ownership over the product lifecycle

Fusion bonded heat exchangers are particularly well suited for continuous operation and critical system applications.

*Performance Comparison at a Glance

*Performance Comparison at a Glance

Copper Brazed BPHE

• Max Temp: Up to 200°C

• Corrosion Resistance: Moderate

• Chemical Compatibility: Limited

• Thermal Efficiency: High

• Hygiene: Moderate

• Ion Contamination: Possible

• Brazing Integrity: May degrade

• Cost: Lower initial cost

Stainless Brazed BPHE

• Max Temp: Up to 400°C

• Corrosion Resistance: Excellent

• Chemical Compatibility: Broad

• Thermal Efficiency: Slightly lower

• Hygiene: High

• Ion Contamination: None

• Brazing Integrity: Excellent

• Cost: Higher upfront

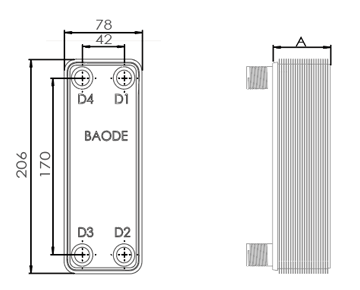

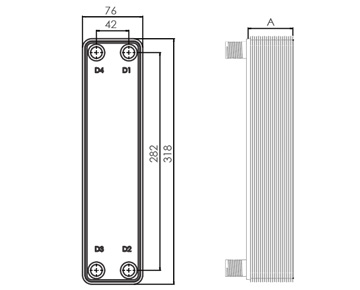

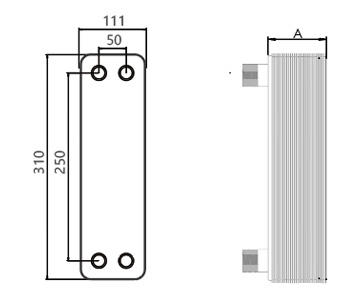

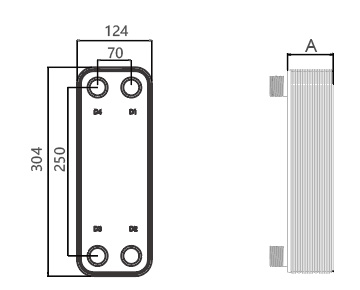

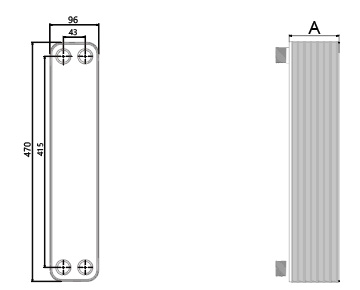

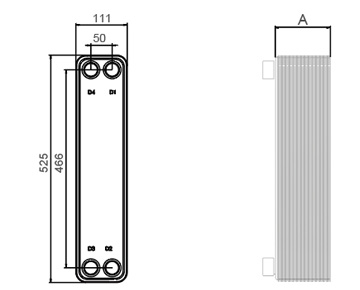

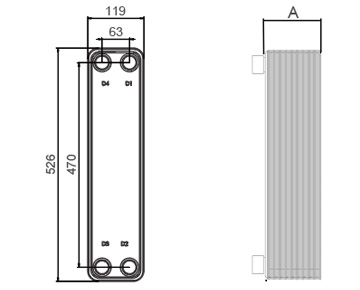

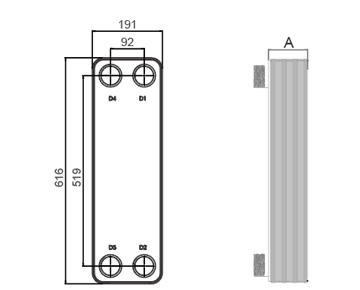

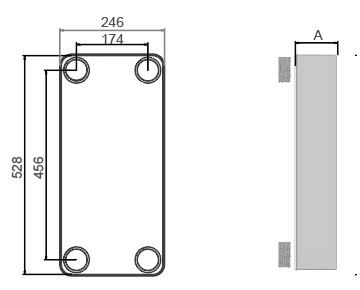

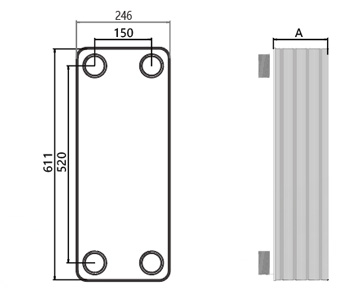

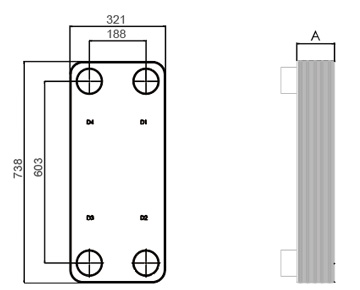

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm

Dimensions in mm