- Menu

- Search For Product Models

Search For Product Models

- cn

In heat exchanger design, the basic equation is:

When the logarithmic mean temperature difference (LMTD) becomes very small, the heat transfer driving force nearly disappears.

For example:

| Hot Side | Cold Side |

|---|---|

| 30 → 10°C | 8 → 28°C |

At this level, the system is approaching the thermodynamic limit.

Any heat exchanger must compensate for the lack of temperature driving force by increasing either:

U – overall heat transfer coefficient

A – effective heat transfer area

Shell & tube heat exchangers typically have:

| Parameter | Typical Value |

|---|---|

| U value | 300–800 W/m²·K |

| Minimum approach ΔT | 8–15 K |

When LMTD falls below 5 K, shell & tube units must rely almost entirely on surface area.

The result is exponentially increasing size, weight, and cost.

For the same duty at ΔTlm = 2K:

This is why shell & tube units become impractical for low-grade heat recovery.

Plate heat exchangers (PHE) achieve:

| Parameter | Typical Value |

|---|---|

| U value | 2000–6000 W/m²·K |

| Minimum approach ΔT | 1–3 K |

The secret lies in:

Corrugated plates

High shear, turbulent micro-channels

Very thin thermal boundary layers

This allows PHEs to maintain high U values even when ΔT is extremely small.

If a PHE is simply made wider:

Flow velocity decreases

Turbulence weakens

Heat transfer coefficient drops

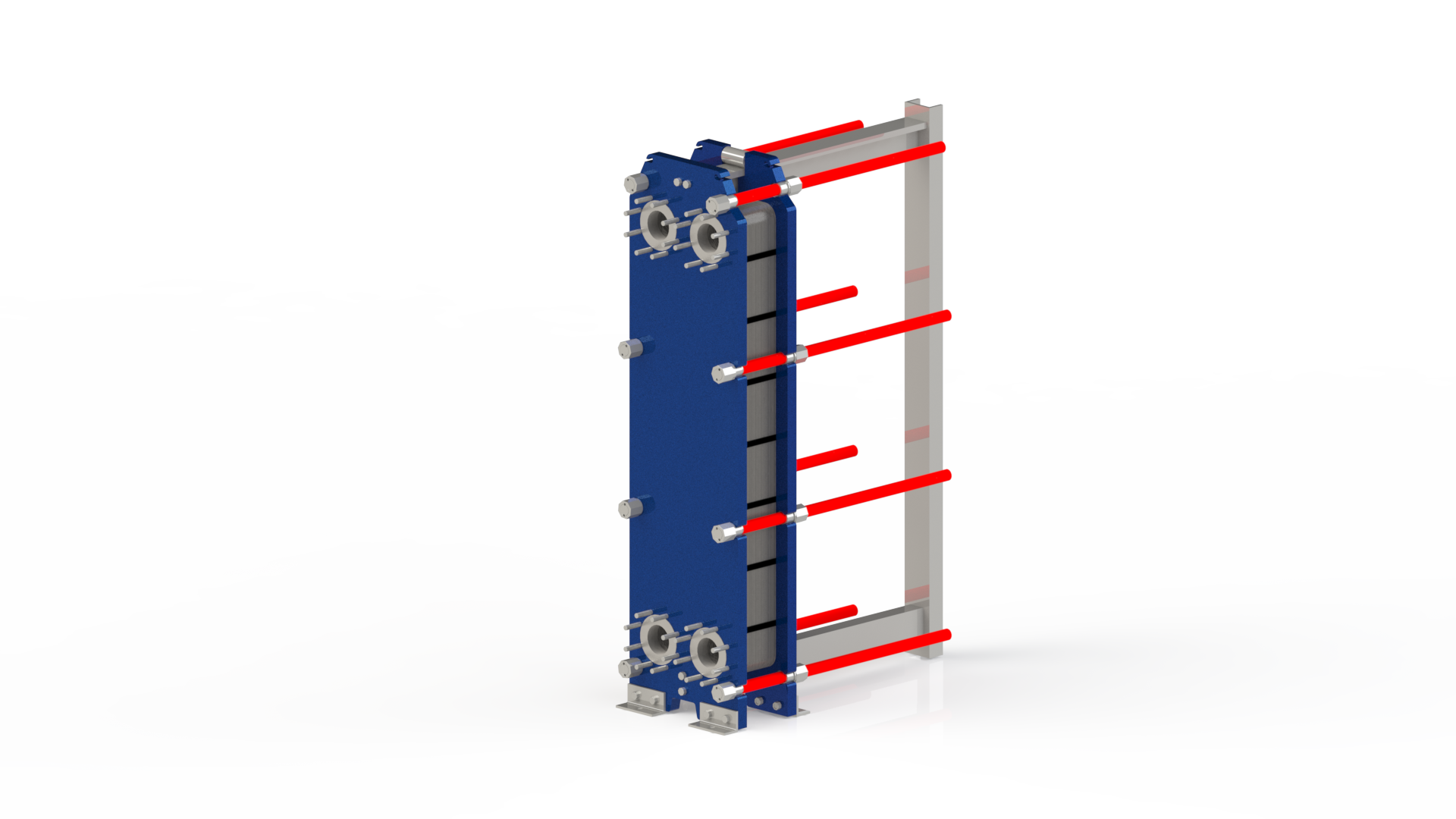

So instead, engineers design PHEs to be:

Long and narrow, not wide and short

This ensures:

High velocity

Strong turbulence

Stable U value

The long flow path also increases the NTU (Number of Transfer Units), which is essential when ΔT is small.

Multi-pass configurations force the fluid to:

Repeatedly change direction

Increase internal velocity

Extend effective contact time

This dramatically increases the convective heat transfer coefficient and allows the exchanger to operate closer to the thermodynamic limit.

| Feature | Engineering Purpose |

|---|---|

| Long plate design | Increase NTU and effective heat path |

| Narrow flow channels | Maintain velocity and turbulence |

| Multi-pass arrangement | Increase U value under low ΔT |

| High pressure drop | Acceptable trade-off for heat recovery |

Small temperature difference is not a design problem – it is a thermodynamic limitation.

Plate heat exchangers overcome this limitation by using fluid dynamics to amplify heat transfer.

Long, narrow, multi-pass plate heat exchangers are therefore not a design choice, but an engineering necessity for low-grade heat recovery.