- Menu

- Search For Product Models

Search For Product Models

- cn

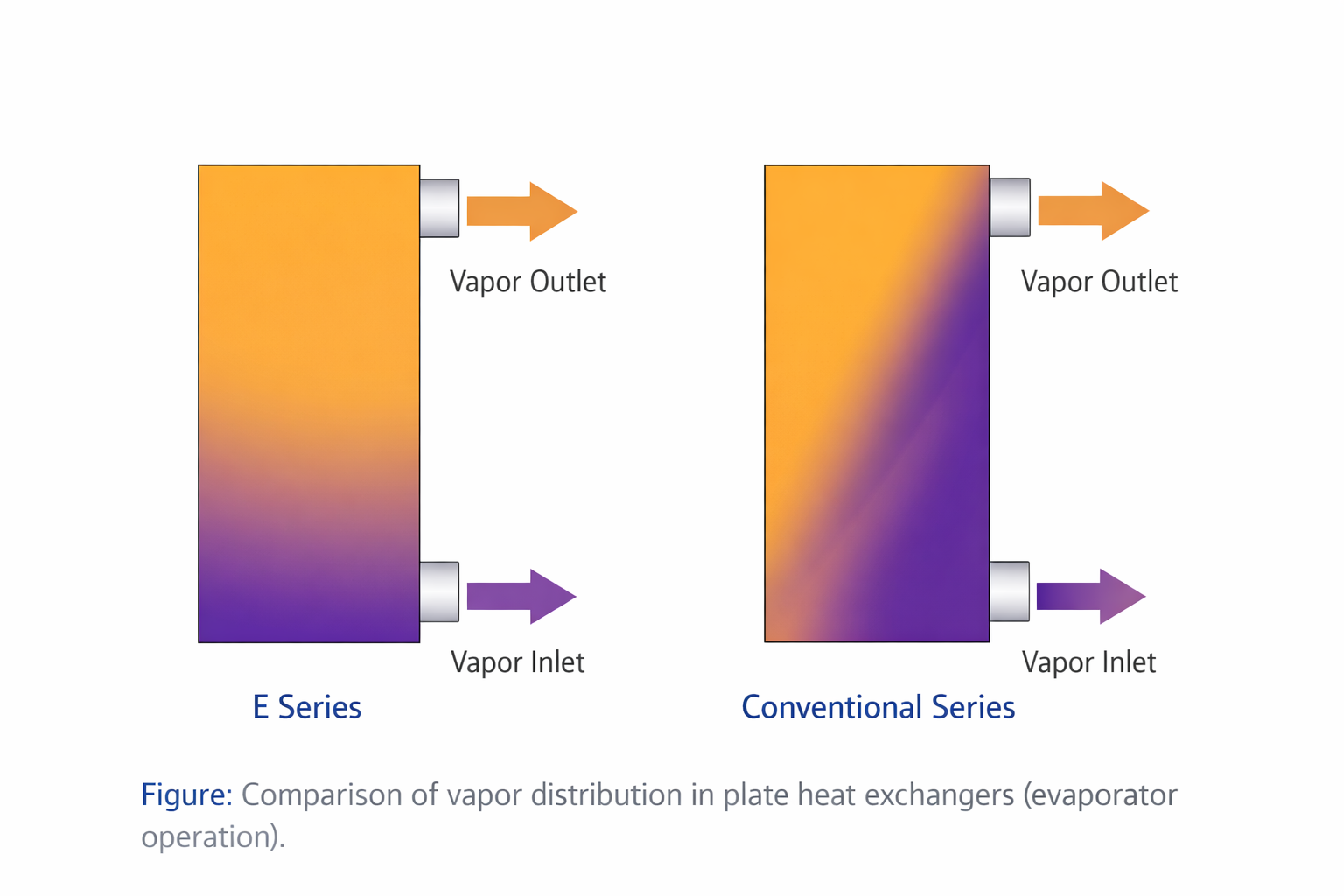

In plate heat exchangers (BPHEs), especially when operating as evaporators, the way fluid is distributed at the inlet has a major impact on performance. Uneven distribution can lead to poor heat transfer, unstable operation, and reduced system efficiency.

To address this challenge, Alfa Laval developed a patented inlet distribution concept known as the Equalancer system. This technology is integrated directly into the heat exchanger plates and is designed to stabilize and equalize refrigerant flow before it enters the main plate channels.

In evaporator applications, the working fluid typically enters the heat exchanger as a two-phase mixture (liquid + vapor). Without proper distribution:

Some channels may receive too much vapor and too little liquid

Other channels may flood with liquid

Local dry-out and excessive superheating can occur

Heat transfer efficiency becomes uneven across the plate pack

These effects reduce the effective heat transfer area and can negatively impact compressor stability and overall system reliability.

The Equalancer system is not a separate mechanical distributor. Instead, it is a pressed geometric structure formed directly in the heat exchanger plate, near the inlet port.

Its purpose is to condition the incoming flow so that each plate channel receives a similar mixture quality and mass flow rate.

Key design objectives of the Equalancer system include:

Stabilizing two-phase flow

Promoting controlled re-mixing of liquid and vapor

Reducing jet effects at the inlet

Improving repeatability from plate to plate

Although compact, the Equalancer consists of several distinct functional elements:

Inlet circular cavity

Receives the incoming refrigerant from the connection port.

Small guiding orifices

Control how the fluid enters the distribution structure and limit direct high-velocity jets.

Crescent-shaped (half-moon) channel

The core of the Equalancer design.

Forces the fluid to follow a curved path

Encourages phase interaction and redistribution

Smooths velocity differences between liquid and vapor

Exit orifice

Releases the conditioned flow toward the main plate flow field.

All these features are formed as part of the plate pressing process, ensuring high dimensional accuracy and consistency.

In evaporator operation, the flow process can be summarized as follows:

Two-phase refrigerant enters the inlet circular cavity.

The fluid passes through a small orifice into the Equalancer structure.

Inside the crescent-shaped channel, the fluid follows a curved path, promoting:

Secondary mixing

Phase redistribution

Reduction of local velocity peaks

The flow exits through another small opening.

The conditioned refrigerant is then distributed into the plate channels more evenly.

This double-mixing effect significantly reduces channel-to-channel imbalance.

The Equalancer system provides several important advantages:

Improved evaporator efficiency

More uniform refrigerant distribution

Reduced superheating variations

Better utilization of heat transfer surface

Stable operation

Less sensitivity to inlet quality variations

Improved system controllability

Negligible impact in condenser mode

Pressure drop introduced by the Equalancer is minimal

No negative effect when the unit operates as a condenser

Manufacturing and reliability benefits

No additional components

Fully integrated into the plate

High repeatability and robustness

Suitable for high-volume production

| Aspect | Conventional Inlet Design | Equalancer System |

|---|---|---|

| Distribution method | Port geometry only | Plate-integrated distribution |

| Two-phase stability | Limited | High |

| Channel flow uniformity | Inconsistent | Highly consistent |

| Additional components | Sometimes required | None |

| Manufacturing repeatability | Moderate | Very high |

The Equalancer system used in Alfa Laval brazed plate heat exchangers is a subtle but critical design feature. By using carefully engineered plate embossing geometry, it achieves effective two-phase flow conditioning in a very small space.

Rather than relying on external distributors or complex assemblies, the Equalancer demonstrates how advanced plate design can significantly improve heat exchanger performance, stability, and reliability, especially in demanding evaporator applications.