- Menu

- Search For Product Models

Search For Product Models

- cn

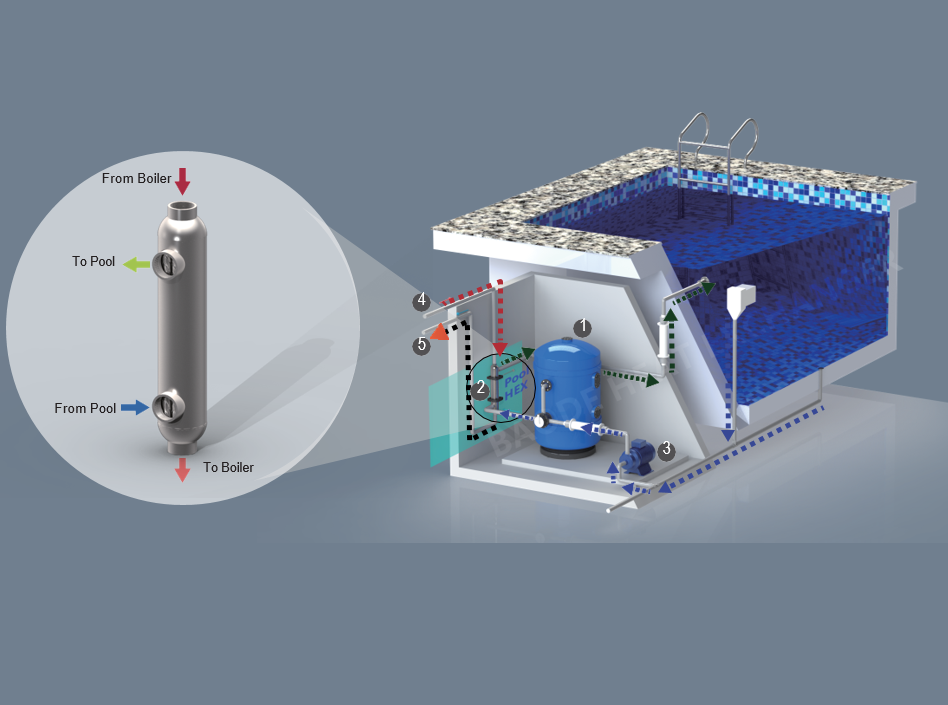

In swimming pool heating applications, shell-and-tube heat exchangers are often more widely used than plate heat exchangers. This preference is based on several practical and technical advantages:

Swimming pool water often contains chlorine, salt, disinfectants, or other corrosive elements.

Shell-and-tube units allow flexible use of corrosion-resistant materials like titanium

Easier to clean and less sensitive to scaling or chemical residue.

Swimming pool circulation systems typically involve large water flow at low pressure.

Shell-and-tube exchangers have larger flow paths and lower pressure drop.

Plate heat exchangers, by contrast, tend to create higher resistance in large-volume systems.

Pool water can contain hair, sand, leaves, or other debris.

Shell-and-tube designs have wider channels that tolerate debris without clogging.

Plate heat exchangers have narrow passages that can easily become blocked.

Shell-and-tube heat exchangers are usually easier to open, inspect, and clean (mechanically or chemically).

Plate heat exchangers may require full disassembly or chemical flushing, which increases maintenance complexity.

In many regions, small shell-and-tube units are more affordable, especially copper-based versions.

They have a longer service life in harsh pool water environments and are less prone to damage from fouling or thermal shock.

When high thermal efficiency is required;

When water quality is well-controlled (with filtration);

When space is very limited and compact size is a priority;

When integrated into a heat pump system or low-temperature loop.

Shell-and-tube heat exchangers are often more popular in pool heating due to their superior durability, clog resistance, flow capacity, and ease of maintenance, especially in real-world conditions where water quality and system loads vary.