- Menu

- Search For Product Models

Search For Product Models

- cn

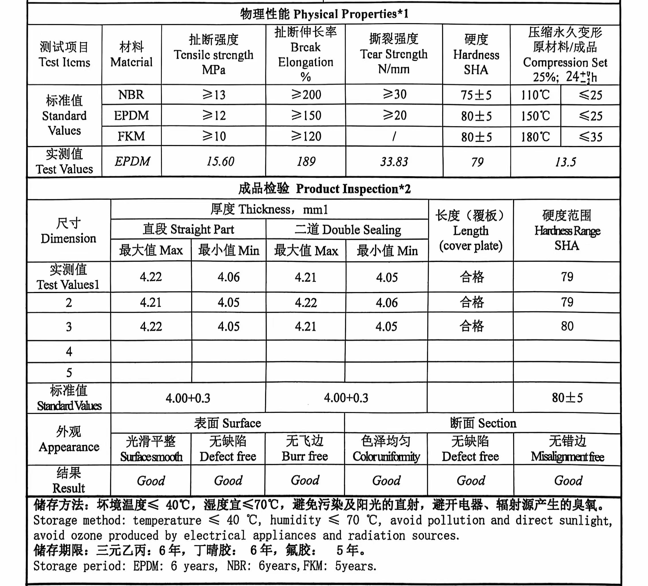

In plate heat exchangers, gasket reliability directly determines sealing performance, operational safety, and service life. While materials such as EPDM, NBR, and FKM are commonly specified based on temperature and chemical compatibility, the long-term performance of a gasket depends equally on manufacturing control.

Mechanical properties listed in a gasket quality certificate are not merely test numbers — they reflect compounding formulation, filler dispersion, vulcanization accuracy, and molding precision.

Tensile strength measures the maximum stress a gasket material can withstand before failure.

Base polymer grade (EPDM/NBR/FKM quality)

Carbon black and reinforcing filler content

Mixing uniformity

Vulcanization temperature and time

If vulcanization is insufficient (under-curing):

Crosslink density is low

Tensile strength decreases

Elastic recovery weakens

If vulcanization is excessive (over-curing):

Material becomes brittle

Micro-cracks may form

Structural strength may degrade

Thus, tensile strength reflects the balance of crosslink density and curing control.

Elongation indicates material flexibility and ability to absorb deformation.

Crosslink density

Plasticizer formulation

Filler proportion

Low elongation often indicates:

Over-curing

Excessive filler loading

Reduced flexibility

Excessively high elongation may suggest:

Insufficient curing

Low structural integrity

In plate heat exchangers, appropriate elongation ensures resistance to thermal cycling and compression stress.

Tear strength determines resistance to crack propagation, especially along sealing grooves.

Polymer chain uniformity

Filler dispersion

Molding pressure

Mold edge precision

Insufficient molding pressure or uneven filler distribution can create micro-voids that weaken tear resistance.

For gaskets operating under high compression, tear strength is critical to prevent edge cracking.

Hardness determines compression behavior and sealing force.

Filler ratio

Sulfur or curing agent dosage

Crosslink density control

If hardness is too high:

Gasket may not conform to plate surface

Risk of insufficient sealing line contact

If hardness is too low:

Excessive compression

Reduced structural support

Premature deformation

Proper hardness ensures uniform compression distribution in the plate pack.

Compression set measures permanent deformation after compression and heat exposure.

This is one of the most important indicators of long-term sealing performance.

Vulcanization uniformity

Crosslink network structure

Heat aging resistance

Polymer formulation stability

Under-cured materials:

Poor elastic recovery

Rapid sealing degradation

Over-cured materials:

Brittle structure

Reduced flexibility

Low compression set ensures:

Long-term sealing integrity

Stable contact pressure

Reduced leakage risk

In real industrial operation, compression set is often more critical than tensile strength.

Beyond mechanical testing, finished gasket dimensions must be tightly controlled.

Mold precision

Injection pressure

Material flow behavior

Temperature stability during curing

Thickness variation directly affects:

Compression distribution

Sealing uniformity

Plate load balance

Even small thickness inconsistencies may lead to localized leakage or uneven stress.

Visual and sectional inspection ensures:

Smooth surface finish

No burrs

No misalignment

Uniform coloration

Surface defects often originate from:

Mold contamination

Temperature fluctuation

Improper demolding

Inconsistent compound mixing

Although simple, surface quality significantly impacts early-stage sealing reliability.

| Material | Temperature Resistance | Typical Application |

|---|---|---|

| NBR | up to 110°C | HVAC and oil systems |

| EPDM | up to 150°C | Water, steam, food |

| FKM | up to 180°C | Chemical and aggressive media |

Material selection must consider:

Operating temperature

Fluid chemistry

Cleaning procedure (CIP)

Pressure cycling conditions

However, even the correct material grade cannot compensate for poor production control.

Mechanical properties are direct indicators of:

Compound formulation accuracy

Filler dispersion quality

Vulcanization precision

Dimensional molding control

Consistent production parameters ensure:

Long-term sealing stability

Reduced maintenance frequency

Lower leakage risk

Improved equipment reliability

Gasket testing is not a procedural formality — it is a reflection of production discipline and engineering responsibility.

In plate heat exchanger applications, gasket performance depends not only on material type but on the integrity of the manufacturing process.

Tensile strength, elongation, tear strength, hardness, and compression set are interconnected properties governed by formulation control, curing accuracy, and molding precision.

Properly controlled production ensures:

Stable sealing performance

Resistance to thermal and mechanical stress

Extended service life

Reduced operational risk

For industrial heat exchanger systems, gasket quality verification is a fundamental component of reliability engineering.

The most critical property is compression set, especially for long-term sealing reliability.

Low compression set ensures that the gasket maintains elastic recovery after compression and temperature exposure. Even if tensile strength is high, excessive permanent deformation can lead to leakage.

In real industrial operation, compression set often determines service life more than tensile strength.

Tensile strength reflects the structural integrity of the material and its resistance to tearing during installation and operation.

However, tensile strength alone does not guarantee sealing performance. It must be balanced with elongation and hardness to ensure flexibility and durability.

Vulcanization determines crosslink density within the rubber structure.

Under-curing leads to low strength and poor elastic recovery.

Over-curing causes brittleness and crack formation.

Proper temperature and time control during curing are essential to ensure stable mechanical properties.

Hardness (Shore A) influences compression behavior and sealing force.

If hardness is too high:

The gasket may not conform properly to the plate surface.

If hardness is too low:

Excessive compression may occur.

Structural support may weaken.

Balanced hardness ensures uniform compression and stable sealing.

Common causes include:

Improper material selection (temperature or chemical incompatibility)

Poor vulcanization control

Excessive compression set

Surface defects from molding

Thermal and pressure cycling fatigue

In many cases, failure is related to manufacturing control rather than material type alone.

Even small thickness inconsistencies can cause:

Uneven compression distribution

Localized leakage

Plate misalignment

Precision molding and strict dimensional control are essential for stable performance.

Replacement intervals depend on:

Operating temperature

Chemical exposure

Pressure cycling frequency

Compression set behavior

In high-temperature or aggressive environments, inspection during scheduled maintenance is recommended.

Not necessarily.

EPDM performs well in water and steam applications.

NBR is more suitable for oil-based fluids.

FKM is preferred for aggressive chemical environments.

Material selection must match operating conditions.

Surface defects such as burrs or molding imperfections may lead to:

Initial leakage

Stress concentration

Early crack propagation

Visual inspection is a simple but critical step in quality assurance.